Beverage Solutions

Beverage producers must appeal to consumers while maintaining quality, safety, and profitability standards. A shift towards sustainable manufacturing alongside trends like sugar reduction, natural flavorings, and dairy alternatives often require new and innovative solutions to meet market demands without hurting the bottom line. Hydrite helps processors address these challenges through creative chemistry solutions to support your production goals.

We distinguish ourselves from other chemical manufacturers and distributors by our ability to be your “one-stop-shop” for all things chemical; one company, one shipment, one point of contact, one purchase order, and just one invoice to process. Hydrite offers chemistry, equipment, and technical expertise to support the production of a wide variety of beverages like:

- Sodas

- Juices

- Protein-based drinks

- Beers

- Wines

- Seltzers

- Ciders

- Smoothies

- Shakes

- Plant-based beverages

- Milk-based beverages

- Teas

- Coffees

- Sports drinks

- Energy drinks

- Kombucha

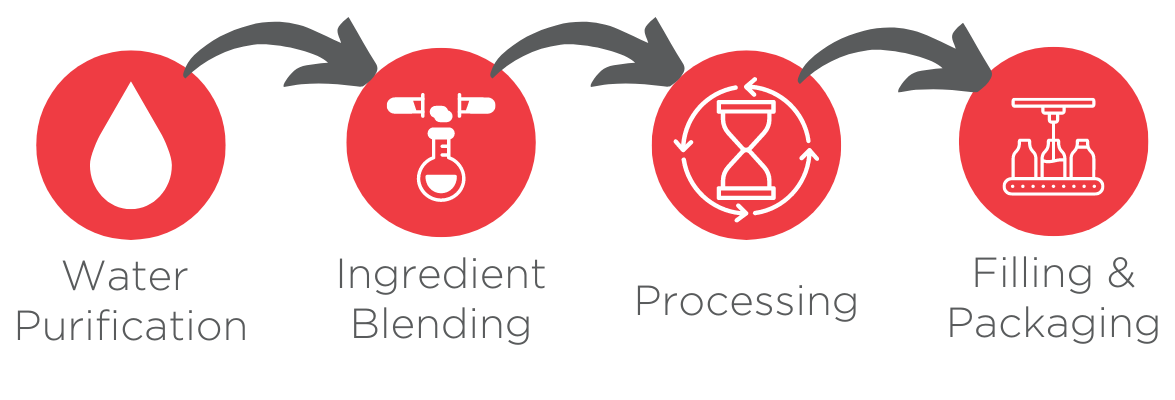

Beverage Production Process

Hydrite is here to help you through every part of the beverage manufacturing process. The beverage production process utilizes many different chemicals each of which play a crucial role in their process.

- Water Purification: This step makes sure the water used in beverages is treated to remove impurities and at the correct pH, providing consistency in the final product. Some chemicals include sodium bisulfite, citric acid, and phosphates.

- Ingredient Blending: This step creates and enhances the flavors seen in many beverages. Ingredients like citric acid and phosphoric acid are often used as flavor enhancers.

- Processing: Beverages are filled into containers like bottles, cans, or cartons in a clean environment to avoid contamination. Containers are often treated with food-safe materials like peracetic acid (PAA) to prevent contamination. Additional post-filling processing like secondary pasteurization or aging may be required after this step depending on the beverage. Some of the processes in this step include:

- Pasteurization (sodium citrate, calcium hydroxide, sodium carbonate)

- Filtration (polymeric membranes)

- Fermentation (ammonium sulfate, yeast)

- Carbonation (carbon dioxide, sodium bicarbonate, citric acid)

- Filling and Packaging: This step readies the beverage for consumers ensuring it is shelf stable and won't prematurely expire using chemistries like citric acid. In this step and throughout the manufacturing process, lubricants are used to keep conveyor belts running smoothly.

solutions for Beverage Manufacturing

Sanitation Chemicals

The plant sanitation process is essential to the safe production of beverages. This process is designed to remove soil, microorganisms, and other contaminants from the manufacturing environment. As such, it plays a crucial role in the manufacturing beverages for our customers. We offer a full range of products—including CIP cleaners, sanitizers, and processing aids—used in the beverage industry for a variety of cleaning and sanitization applications.

Water Treatment

Most beverage manufacturing plants are required to meet stringent water treatment discharge regulations. Hydrite has the chemistry and expertise to help you meet your specific regulations. As your supplier, we will analyze your current chemistry and process, and implement cost reduction strategies.

- Coagulants for clarification

- Polymers and flocculants for liquid/ solid separation

- BOD/Solids reduction

Processing Aids

We supply products to assist with increased production throughput and improving operational efficiencies. Processing aids help control unwanted scale formation and lead to longer and more efficient product runs. At Hydrite our patented processing aids are the result of years of research and field testing to create the best product options for the beverage industry.

Foam Control

Hydrite manufactures a full line of defoamers for the beverage manufacturing industry, including application solutions in fermentation, dairy production, and protein extraction. We offer silicone and non-silicone based food grade defoamers for use in processing, CIP and wastewater, along with the associated feed and control equipment to manage your defoaming costs.

Membranes

Hydrite offers a full range of services designed to implement and maintain effective chemical membrane cleaning protocols in your facility. Our sanitation offerings extend from effective detergents to in-plant support and training, ensuring that you not only receive the right chemical products but that your employees use them properly.

Hydrite works side by side with you to find creative solutions to meet the strict standards accompanying your product formulations. You can depend on us for reliable, high quality food ingredients to help you meet your customers’ expectations.

Applications & Opportunities

- pH buffering technologies for taste stability

- Liquid citric acid systems tailored for product consistency

- Plant-based ingredients and stabilizers

- Liquid sweetener concentrates for ease in formulation

- Whey protein stabilizers for better processing

- Nutritional fortification blends

- Proven food safety sanitation programs

Beverage Ingredient Examples

- Liquid sodium benzoate

- Citric acid and citrates

- Phosphoric acid and phosphates

- Lactic acid

- Liquid potassium sorbate

Hydrite Equipment: FEED+

Affordable, dependable, flexible, and robust, Hydrite chemical equipment systems are designed to optimize chemical delivery and application in the beverage processing plant. Creative solutions like the FEED+ chemical allocation and dispensing system support time-based secondary container filling, concentration maintenance utilizing a recycle time option, and zoned lubricant dispensing.

FEED+ Features

- Time and date stamp for each output activated

- Time stamp for how long each output is activated

- Quick install and commission process

- Robust and flexible technology

- Capable to control and deliver to 16 locations individually

Explore more Hydrite-exclusive and off-the-shelf equipment technology options to take control of your beverage production line. View All Equipment.

Conveyor Lubricants

Hydrite offers fatty acid, synthetic, and dry lubricants for the beverage processing plant used in applications like filling, labeling, packaging, palletizing, washing, and more:

- Hydrilube HD No. 675: Tabletop & in-floor fatty acid lubricant

- Sani-PET No. 683: PET-compatible liquid conveyor lubricant

- Glide Right No. 660: Synthetic, low-foaming tabletop lubricant

- Dry Glide No. 661: Silicone dry lubricant applied via brush for PET, glass, and can conveyor systems

Safety and compliance are important considerations when introducing a food-grade lubricant to the manufacturing floor, which is why choosing a reputable supplier is critical. With 95+ years in business, Hydrite is a respected national leader in sanitation and cleaning chemistry for the food industry, with core building blocks focused around safety and quality.

Hydrite food safety program

Hydrite offers expertise on food safety programs designed to increase your food safety and protect your brand. We assess the specific needs of your company to create solutions that work effectively while delivering the greatest value. Our extensive line of sanitation products, coupled with our technical support, has gained the trust of some of the world’s top manufacturers for their plant sanitation needs. We also offer trainings and educational programs to help increase your knowledge and understanding of food safety and improve your company’s operational efficiencies. Trainings cover topics like cleaning dynamics, CIP verification & validation, food microbiology, and preventative sanitation - just to name a few. An effective food safety program equips your company to apply these techniques to everyday working operations and effectively uphold food safety practices. View upcoming programs.

The RITE Team® Training Instructors

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to support beverage manufactuers through technical training, program development, and adjacent technology. Meet the Team

Steve Tienvieri

Senior Lead Microbiologist

26+ Years of Experience

Joel Cook

Senior Technical Manager

22+ Years of Experience

Glen Giersch

ATS Program Manager

28+ Years of Experience

Carl Garcia

Membrane Technical Manager

30+ Years of Experience

Contact Us

Connect with a Hydrite representative to learn more about beverage solutions for your production facility.