FOOD EQUIPMENT TECHNOLOGY SOLUTIONS

Hydrite provides creative chemical equipment options for a wide variety of industries, including a robust portfolio for the food industry. Affordable, dependable, flexible, and robust, these systems are designed to optimize chemical delivery and application. When working with customers, the Hydrite equipment technology team considers five key factors:

![]()

Chemical Equipment Applications

Hydrite chemical equipment solutions cover a variety of applications and can be customized to fit unique processing and manufacturing requirements.

- Allocating, analyzing and documenting concentrations of cleaning, sanitation and intervention chemistries

- Chemical concentration controlling and recording

- CIP and COP

- Day tank dispensing

- Dry and liquid chemical blending

- PAA Product Control, Delivery & Real-Time Concentration Monitoring

- Formula recipe and make down

- Polymer blending

- Reuse, reclaim, or batch

- Secondary container dispensing

- Telemetry, monitoring, and logistics

- Wastewater treatment and control

Choose between Hydrite-exclusive and off-the-shelf options that meet your unique application needs. Hydrite-exclusive equipment technology is the industry-leading choice for customers, with comprehensive support including installation, operation training, preventative and reactive maintenance, and real-time troubleshooting. Download the brochure.

Choose between Hydrite-exclusive and off-the-shelf options that meet your unique application needs. Hydrite-exclusive equipment technology is the industry-leading choice for customers, with comprehensive support including installation, operation training, preventative and reactive maintenance, and real-time troubleshooting. Download the brochure.

Chemical Storage, Handling & Monitoring Equipment

Chemical Storage, Handling & Monitoring Equipment

Safely store and blend chemicals on site with robust, flexible technology designed to maintain product integrity.

- Bulk Storage & Handling

- Blending or Make Down

- Secondary Container Filling

Hydri-Vision: Hydri-Vision is patented technology for collecting, analyzing and documenting concentrations of cleaning, sanitation and intervention chemistries. Food safety, verification and validation as well as quality of an applicable finished product are foundational to this creative solution. Read the case studies: a third-party accredited study's findings + SQF certification thanks to Hydri-Vision.

Hydri-Vision: Hydri-Vision is patented technology for collecting, analyzing and documenting concentrations of cleaning, sanitation and intervention chemistries. Food safety, verification and validation as well as quality of an applicable finished product are foundational to this creative solution. Read the case studies: a third-party accredited study's findings + SQF certification thanks to Hydri-Vision.

Hydri-Vision DLX: An enhanced model of the Hydri-Vision, the Hydri-Vision DLX includes the ability to measure and record pH and titrations automatically and in real time, making it a second set of eyes to support food safety and sanitation programs. Monitor up to 10 products from 12 supplies.

Hydri-Vision DLX: An enhanced model of the Hydri-Vision, the Hydri-Vision DLX includes the ability to measure and record pH and titrations automatically and in real time, making it a second set of eyes to support food safety and sanitation programs. Monitor up to 10 products from 12 supplies.

Hydri-Vision RT: This technology uses live analytics to analyze chemical and sanitizer concentrations in CIP programs. It provides insights to reduce time, chemistry, energy, and water usage. By tracking concentrations per product and circuit, it helps optimize cleaning protocols while protecting production schedules, equipment, and food safety.

Hydri-Vision RT: This technology uses live analytics to analyze chemical and sanitizer concentrations in CIP programs. It provides insights to reduce time, chemistry, energy, and water usage. By tracking concentrations per product and circuit, it helps optimize cleaning protocols while protecting production schedules, equipment, and food safety.

FMS+: This portable technology services up to 16 flowmeters at once, managed with an HMI interface and remote or local data access. It's compatible with Allen Bradley PLCs, Seametrics flowmeters, and Keyence flowmeters. Read more +

FMS+: This portable technology services up to 16 flowmeters at once, managed with an HMI interface and remote or local data access. It's compatible with Allen Bradley PLCs, Seametrics flowmeters, and Keyence flowmeters. Read more +

Bulk or Secondary Container Storage & Telemetry: Customizable and modular program to support all your liquid storage and level monitoring needs throughout a facility. Assmann, Poly Processing, and Anova support this program by identifying significant opportunities for reducing transpotation, logistics, or order fulfillment costs all while storing and level monitoring as efficient and safe as possible.

Bulk or Secondary Container Storage & Telemetry: Customizable and modular program to support all your liquid storage and level monitoring needs throughout a facility. Assmann, Poly Processing, and Anova support this program by identifying significant opportunities for reducing transpotation, logistics, or order fulfillment costs all while storing and level monitoring as efficient and safe as possible.

Intelli-Fil (Coming Soon): A system that transfers chemistry from bulk, totes, or drums to smaller containers. This process is primarily controlled by calibrated time, although flow could be an option. Having a system like this is a strong safety measure in that it minimizes the operator’s interaction with chemistry.

Intelli-Fil (Coming Soon): A system that transfers chemistry from bulk, totes, or drums to smaller containers. This process is primarily controlled by calibrated time, although flow could be an option. Having a system like this is a strong safety measure in that it minimizes the operator’s interaction with chemistry.

Chemical Delivery & Control Equipment

Consistently and accurately apply chemicals in complex and challenging applications while ensuring compliance and quality control through regulating how chemicals are proportioned, monitored, and logged. Choose from customizable configurations that integrate into existing manufacturing lines.

- Dispensing & Allocation

- Foam or Gel Systems

- Lubrication

- Foam Control

- Product Usage Monitoring

- Clean-in-Place (CIP) & Clean-Out-of-Place (COP)

- Intervention

- Secondary Container Filling

SLM™: Hydrite's first-gen clean-in-place technology helps users identify unique opportunities for maximizing optimization and minimizing risk, with demonstrated success of reducing CIP time, water usage, and chemical spend.

SLM™: Hydrite's first-gen clean-in-place technology helps users identify unique opportunities for maximizing optimization and minimizing risk, with demonstrated success of reducing CIP time, water usage, and chemical spend.

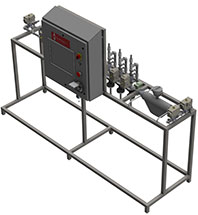

Hydri-SLM RT™: Building off of Hydrite's SLM™ technology, the new Hydri-SLM RT™ in-line solution uses PC-based, sensor technology to collect, visualize, and interpret data in real time.

Hydri-SLM RT™: Building off of Hydrite's SLM™ technology, the new Hydri-SLM RT™ in-line solution uses PC-based, sensor technology to collect, visualize, and interpret data in real time.

Feed+: Chemical allocation and dispensing system which includes 8 or 16 time options. The Feed+ can be used in a variety of ways like time-based secondary container filling, concentration maintenance utilizing a recycle time option, or as a zoned lubricant dispenser.

Feed+: Chemical allocation and dispensing system which includes 8 or 16 time options. The Feed+ can be used in a variety of ways like time-based secondary container filling, concentration maintenance utilizing a recycle time option, or as a zoned lubricant dispenser.

Feed Flo+: A recipe-based flowmeter dispenser, the Feed Flo+ delivers up to eight products to a maximum of four destinations. All products are pumped through a single header with a single flowmeter with water flush between any chemistry. Optional chlorine bypass is available when delivering chemistry to sensitive equipment.

Feed Flo+: A recipe-based flowmeter dispenser, the Feed Flo+ delivers up to eight products to a maximum of four destinations. All products are pumped through a single header with a single flowmeter with water flush between any chemistry. Optional chlorine bypass is available when delivering chemistry to sensitive equipment.

CCR+: A conductivity controller designed primarily for use on CIP and COP systems, controlling up to four systems. The CCR+ controls chemical concentrations of caustic and acid washes by adjusting to a conductivity setpoint. It can alarm in either a low or high conductivity setting. Chlorine or sanitizers can also be controlled by the unit with a time feed function.

CCR+: A conductivity controller designed primarily for use on CIP and COP systems, controlling up to four systems. The CCR+ controls chemical concentrations of caustic and acid washes by adjusting to a conductivity setpoint. It can alarm in either a low or high conductivity setting. Chlorine or sanitizers can also be controlled by the unit with a time feed function.

Hydri-Pro: Hydri-Pro is patent pending technology for allocating and dispensing cleaning, sanitation and intervention chemistries. Simplicity of its design as well as the accuracy and speed of chemical delivery is foundational to this creative solution. Read the case studies: automation at a dairy co-op + improved accuracy in a greenfield expansion.

Hydri-Pro: Hydri-Pro is patent pending technology for allocating and dispensing cleaning, sanitation and intervention chemistries. Simplicity of its design as well as the accuracy and speed of chemical delivery is foundational to this creative solution. Read the case studies: automation at a dairy co-op + improved accuracy in a greenfield expansion.

Hydri-Pro Lite: The Hydri-Pro Lite model features the same benefits as the standard Hydri-Pro with a reduced footprint, accommodating up to six destinations and six chemicals with the ability to be wall mounted.

Hydri-Pro Lite: The Hydri-Pro Lite model features the same benefits as the standard Hydri-Pro with a reduced footprint, accommodating up to six destinations and six chemicals with the ability to be wall mounted.

Contact

Can’t find exactly what you’re looking for? Connect directly with a member of the Hydrite technology team to discuss your unique application requirements.