Dairy Solutions

With Hydrite as your single source chemical supplier, you will optimize your food safety and sanitation to make the best products on the market. Our job is to find creative solutions to increase your profitability and run your plant more efficiently – and we love what we do for you. Your profitability is directly linked to production efficiencies. Hydrite provides solutions designed to shrink the sanitation window, give you more production hours in your day, and produce safer dairy products; this includes applications like:

- Milk (whole, skim, 2%, evaporated, condensed, etc.)

- Cheese (cheddar, mozzarella, gouda, brie, etc.)

- Yogurt (plain, Greek, flavored, etc.)

- Butter

- Cream (heavy cream, half-and-half, etc.)

- Sour Cream

- Buttermilk

- Cream Cheese

- Kefir

- Ice Cream

- Whey (whey protein, whey concentrate, whey isolate)

Solutions for dairy processing

Sanitation Chemicals

The sanitation of your plant has a direct impact on the shelf life and quality of the products you produce. The program you implement impacts your production efficiencies, effluent costs, and the life of your equipment. Hydrite produces a complete line of sanitation products for the dairy industry including:

- CIP cleaners

- Sanitizers

- Manual cleaners

- Foam cleaners

- Conveyor lube

- Membrane cleaners

- Single shot cleaners

- Foot foamer compound

- Hand sanitation products

- Wetting agents/water conditioners

Membrane Technologies

Hydrite offers a full range of services designed to implement and maintain effective chemical membrane cleaning protocols in your facility. Our sanitation offerings extend from effective detergents to in-plant support and training, ensuring that you not only receive the right chemical products but that your employees use them properly.

- Apollo No. 327: A nonionic surfactant additive enhancing membrane filtration system cleaning. Approved for UF and MF polymeric membranes in all food plants.

- Hydriflux NP No. 366: A concentrated NaOH based liquid, non-chlorinated alkaline cleaner for reverse osmosis and filtration in membranes.

- Membrane Additive No. 531: A low odor, liquid potassium metabisulfite solution for reverse osmosis and filtration for membranes.

Ingredients

Hydrite works side by side with you to find creative solutions to meet the strict standards accompanying your product formulations. You can depend on us for reliable, high quality dairy ingredients to help you meet your customers’ expectations, with advantages like:

- Technologies for modifying dairy proteins to improve melting characteristics & stability

- Optimizing whey protein yields in operations

- Nutritional fortification ingredients

- pH buffering to extend shelf life

- Proven food safety sanitation programs

Platform Products

In addition to manufacturing plant sanitation chemicals, Hydrite is one of North America’s largest chemical distributors. We supply a wide array of commodities such as:

- Caustic

- Bleach

- Nitric acid

- Lime

- Phosphoric acid

- Sulfuric acid

- Glycol

Water Treatment

Hydrite offers a complete line of chemicals for wastewater treatment. We provide the feed equipment, technical service, and engineering to help you minimize costs and comply with local regulations.

- Acids and caustic for pH adjustment

- Coagulation for clarification

- Odor control

- Polymers and flocculants for separation

- Phosphorus reduction

- BOD/solids reduction

Foam Control

Our foam control group offers a full line of defoamers with regulatory approvals. We craft products to eliminate foam which can increase your overall production quotas. We offer:

- Silicone based food grade defoamers

- Non-silicone based food grade defoamers

- CIP and wastewater defoamers

- Feed and control equipment

Service and Support

Our focus on training your employees will help you achieve your goal of consistent finished product quality in a safe environment. You will appreciate our unparalleled technical emphasis and passion for true customer service. Many of our service and technical support personnel have prior food industry production experience, making them a valuable resource for their customers.

Production Optimization

Hydrite provides processing aids to help you achieve longer production runs, better finished product quality, easier and faster cleanups and reduced energy costs. Our aids, combined with the expertise of our technical and engineering experts, can increase production of:

- Heat exchangers

- Membranes

- Evaporators

- Crystalizers

- Refiners

- Dryers

Engineering & Equipment

To ensure safe, accurate and economical chemical usage, our service specialists and engineering staff investigate and recommend the proper chemical feed and control equipment.

- Detergent feed systems

- Bulk and tote chemical storage and transfer

- Central sanitizing systems

- Central doorway foaming systems

- Liquid ingredient storage and feed systems

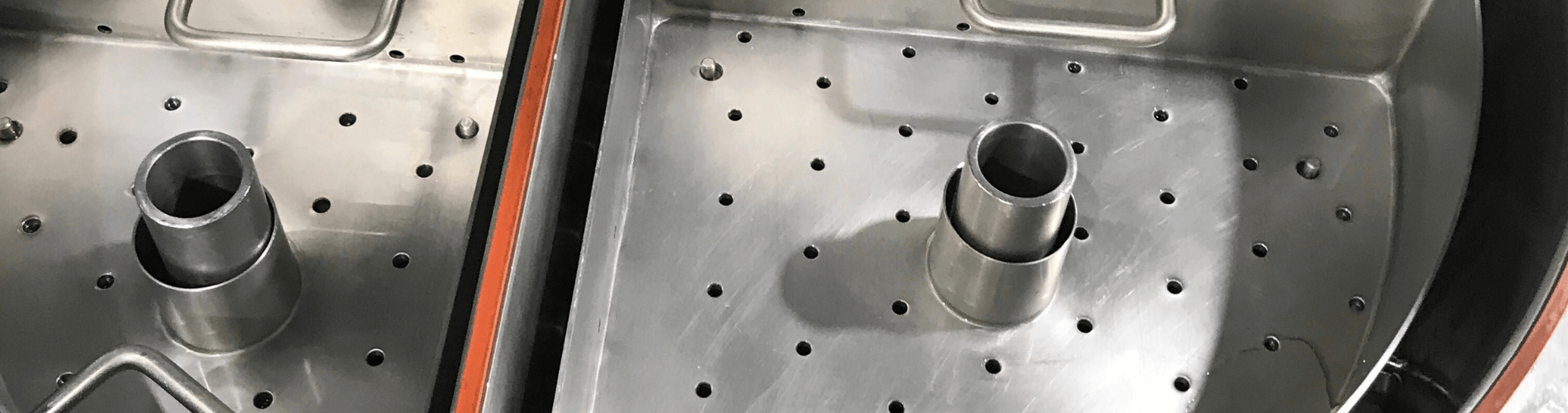

Application Spotlight: Dairy Evaporators

Production floor employees know how much of a nuisance a clogged evaporator tube can be. Running almost 24/7, keeping evaporators clean is crucial for maintaining efficiency, product quality, and safety in a dairy production facility. Regular cleaning and maintenance of evaporators extends operational life, saves on repair and replacement costs, and prevents equipment damage or costly downtime. More importantly, proper cleaning helps prevent bacterial growth and contamination, ensuring the final products meet safety standards and maintain their desired taste and texture.

Hydrite is proud to offer best-in-class proprietary evaporator processing aids like Delta No. 594, Prolong Plus No. 598, and Poly-Sperse No. 543. These solutions help prevent scale build up, mineral fouling, white scorch particles, and reduced throughput.

Hydrite Technology

Affordable, dependable, flexible, and robust, Hydrite chemical equipment systems are designed to optimize chemical delivery and application in the dairy processing plant. Choose from Hydrite-exclusive and off-the-shelf options that meet your unique application needs. View All Equipment.

Hydri-Vision

Hydri-Vision is patent pending technology for collecting, analyzing, and documenting concentrations of cleaning, sanitation, and intervention chemistries. Food safety, verification and validation as well as quality of an applicable finished product are foundational to this creative solution

Hydri-Pro

Hydri-Pro is patent pending technology for allocating and dispensing cleaning, sanitation and intervention chemistries. Simplicity of its design as well as the accuracy and speed of chemical delivery is foundational to this creative solution.

Hydrite Training

Hydrite offers training and educational programs to help increase your knowledge and understanding of food safety, and improve your company’s operational efficiencies. Our programs cover topics such as cleaning dynamics, CIP verification & validation, food microbiology, and preventative sanitation - just to name a few. An effective food safety program will enable your company to apply these techniques to everyday working operations and effectively uphold food safety practices. Grow your knowledge with Hydrite

Steve Tienvieri

Senior Lead Microbiologist

26+ Years of Experience

Joel Cook

Senior Technical Manager

22+ Years of Experience

Glen Giersch

ATS Program Manager

28+ Years of Experience

Carl Garcia

Membrane Technical Manager

30+ Years of Experience

Technical Expertise at Your Fingertips

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to support dairy processors through technical training, program development, and adjacent technology. Meet the Team

Contact Us

Connect with a Hydrite representative to learn more about dairy solutions for your production facility.