Thin Film Evaporation

Evaporators are used to separate the components of a process liquid based on volatility. The basic process involves applying heat to a liquid which causes it to evaporate, thereby leaving the less volatile substance behind. The more volatile – and now gaseous – substance is then condensed and collected at a separate location.

Traditionally, batch or continuous types of evaporators such as natural/forced circulation, falling and rising film, and climbing and falling plate evaporators have been used successfully with a range of process liquids. However, these evaporators have proven to be inefficient with high-boiling, viscous, fouling, and heat sensitive liquids.

The design of thin film evaporators (also referred to as wiped film evaporators) allows them to successfully separate difficult-to-handle products. This method uses indirect heat transfer and mechanical agitation to evaporate a thin layer (0.1 mm to 1.0 mm) of flowing substance under controlled conditions.

How Do Thin Film Evaporators Work?

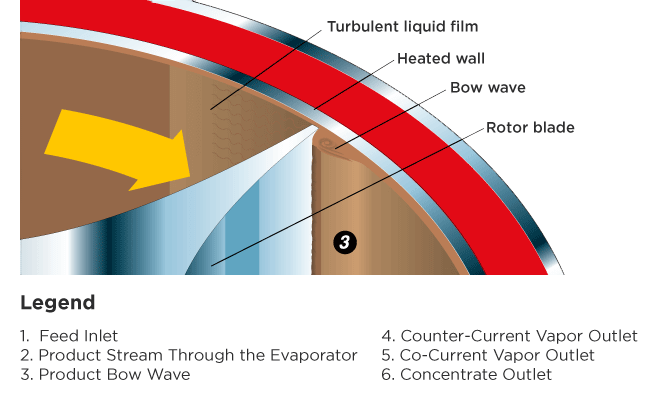

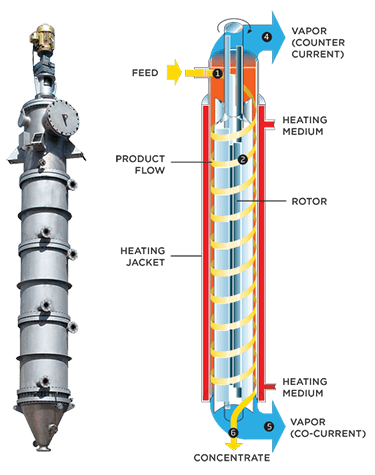

The key to the efficiency of thin film evaporators is their ability to evaporate the target solution at relatively low temperatures with minimum residence time in the evaporator. This is due to operating the evaporator under vacuum conditions and the high speed rotor creating a thin liquid film. The main component of the thin film evaporator consists of a rotor/wiper encased in a cylindrical heating jacket. The process can be broken up in several stages:

- The product first enters above the heated zone where it is evenly distributed against the inner wall of the heating jacket by the rotating wipers.

- A rotor then forms a thin turbulent layer of liquid, which creates ideal heat flux and mass transfer conditions.

- The end result is rapid evaporation of the more volatile substance, which is then expelled from the heating cylinder to be condensed or subjected to further processing.

- The less volatile materials are collected and sent to the discharge nozzle.

Video and imagery courtesy of LCI Corporation

Thin Film Evaporation Advantages

Thin film evaporation offers several advantages over other types of conventional evaporation processes. These include:

- Significantly reduced residence time

- Fast and efficient heat transfer

- Reduced pressure drop

- Ability to process high-viscosity and high-solids materials

- Ability to process materials that are sensitive to thermal degradation or prone to fouling

- High evaporation ratios (>95%)

- Easy to clean/maintain equipment

Thin film evaporation is typically used for specialty applications in the chemical, food and beverage, pharmaceutical, biotechnology, and nuclear industries, among others. Although the application across sectors varies, thin film evaporators are commonly used to perform specific operations such as concentration, resource recovery, devolatilization, purification, distillation, and stripping.

Hydrite Legitimate Recycling Services

Hydrite offers legitimate recycling services like thin film evaporation, fractionation, vacuum distillation, and drying at our Cottage Grove (WI) location. As a Part B permitted treatment storage disposal facility, we’re able to handle a wide variety of operations like:

- Concentration

- Resources Recovery

- Devolatilization

- Purification

- Distillation

- Stripping

Supported by a state-of-the-art laboratory and decades of experience in recycling and waste management, our technical team of experts successfully handle waste products in compliance with federal, state, and local environmental laws and regulations. Additionally, we can identify substantial cost savings for minimizing waste disposal.

Contact Us

To learn more about how thin film evaporation can be used in your specific application, contact the waste & recycling team.