Specialty Equipment Technology Solutions

Hydrite offers a variety of industry and application specific equipment technology designed to promote operational efficiency across the plant. Backed by decades of field and industry experience, Hydrite reps are equipped to identify the right fit for your application requirements and support evaluation, installation, and ongoing support.

Peracetic Acid Equipment

Peracetic Acid (PAA) is a powerful disinfectant due to its high oxidizing potential, effectiveness against a broad range of microorganisms and its favorable environmental profile. Due to peracetic acid’s reactive and corrosive nature, specialized equipment may be needed in some facilities. To meet this need, Hydrite offers bulk PAA delivery and dosing equipment that makes taking advantage of this powerful oxidizer easier and more economical, no matter the industry. Portable PAA transfer pumps and metering pumps are designed for shock, slug, and continuous treatments with easy integration into an existing production line. Customers can take advantage of economical bulk PAA with a state-of-the-art transportation system delivered by Hydrite's private, on-time fleet.

PAA Bulk Delivery

PAA Portable Transfer Pump

ORP or pH

PAA Bulk Delivery

Safe, economical bulk PAA with a state-of-the-art transportation system delivered by Hydrite’s private, on-time fleet.

PAA Bulk Delivery

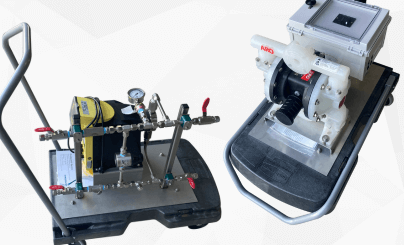

Portable PAA Transfer Pump

Ideal for continuous or slug treatment with control system integration, plastic safety enclosure, and a stationary skid/pump.

Portable PAA Transfer Pump

ORP and pH

Application-specific instrumentation to support custom equipment packages for accurate measurement, monitoring, and control of peracetic acid or hydrogen peroxide.

ORP and pH

Inline Static Mixing

For customers that would like to feed product to application areas via water dilution, Hydrite offers an in-line, static mixer to ensure that the product delivered is uniform and consistent. The in-line, static mixer mixes the defoamer/antifoam with the dilution water. This equipment will reduce “gelling” and lower maintenance costs as the lines should require less care.

Entrained Air Monitoring

Hydrite has collaborated with Emerson to bring unparalleled accuracy in monitoring entrained air (bubbles) within a given fluid system at a microscopic level to more accurately dose defoamer/antifoam. This is the most accurate method available to better control dosing and provide efficient foam control with the operating system. Benefits include:

- Immediate data

- On-line dosing control feedback loop

- Reduced maintenance

- Cost control

Beyond specialty applications, Hydrite has a robust portfolio of equipment technology designed for food manufacturing and water treatment applications.

Contact Us

Connect with the Hydrite technology team to learn more about specialty equipment technology solutions for your facility.