Sugar Processing

Sugar is primarily harvested from sugar cane and sugar beets. Sugar beets are a root vegetable that grow in cooler climates, while sugar cane plants are grasses that can grow up to 20 feet tall and are often found in tropical climates. Sugar beet and sugar cane are go-to sources for sugar because they have high sucrose content and sweetness purity. For both, the refining process removes all impurities and the surrounding plant matter, leaving only pure sucrose for consumption or further processing.

How are sugar beets processed?

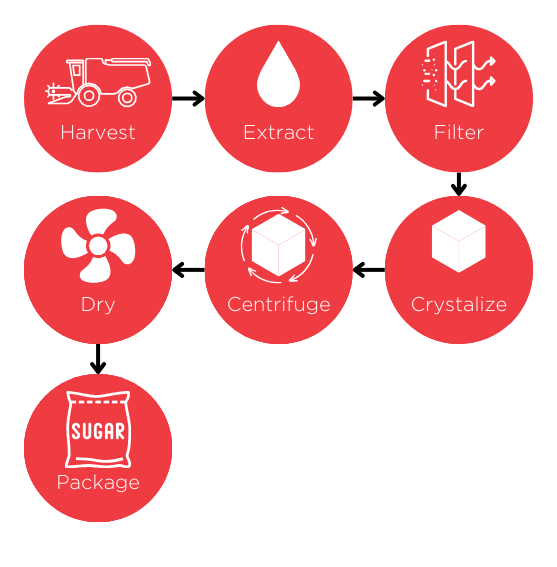

- Sugar beets are grown in many different regions, such as Minnesota, Michigan, Wyoming, Idaho, and California and then transported to nearby processing plants.

- At the processing plants, the beets are cleaned and cut into thin strips, known as cossettes. These cossettes are then placed in a large tank called a diffuser, where raw juice is extracted.

- The raw juice is filtered to remove any impurities, resulting in a syrup.

- Sugar crystals begin to form from the syrup as water is evaporated from the juice and boiled in a vacuum.

- In a centrifuge, the sugar crystals are separated from the remaining syrup.

- The crystals are then dried.

- Finally, the sugar is packaged and distributed.

Uses of Sugar Beets

Ice Melt

Sugar beet juice and salt melts ice more effectively.

Table Sugar

Table sugar is often used to sweeten beverages, enhance the flavor of baked goods, and preserve fruits in jams and jellies.

Animal Feed

Sugar can be added to animal feed to provide a source of energy, improve palatability, and stimulate feed intake in livestock and poultry.

Biofuels

Sugar is used in the production of biofuels where it is fermented by microorganisms to produce alcohol that can be used as a renewable energy source.

Peracetic Acid (PAA)

PAA is often used in the sugar industry to combat odors and mitigate infection that can disrupt processing and resulting yield. Hydrite offers bulk PAA delivery and dosing equipment that makes taking advantage of this powerful oxidizer easier and more economical, no matter the industry. Portable PAA transfer pumps and metering pumps are designed for shock, slug, and continuous treatments with easy integration into an existing production line. Customers can take advantage of economical bulk PAA with a state-of-the-art transportation system delivered by Hydrite's private, on-time fleet.

Hydrite Solutions

Hydrite offers a variety of solutions to support efficient and profitable sugar production. We strive to be the preeminent supplier of process chemicals for the sugar industry. Our centrally-located manufacturing facilities, regional warehouses, and strategically placed sales representatives allow us to properly serve our customers with all their chemical needs.

Clean In Place (CIP) & Boil Out Aids

Hydrite offers a number of products listed to help with CIP/boilouts. Our line includes oxidizer cleaners, chelators, carbon cleaners, and acid cleaners. This also includes protocols for resin fractal cleaning, and a number of technical personnel with expertise and support when needed.

Odor Control

To combat undesirable odors, Hydrite has developed technology to assist in odor abatement at the sugar mills. Advanced Oxidation Technology (AOT) is now just one of the tools along with peroxides/oxidizers, masking agents, countervalent/covalent products, and bioaugmentation. The system destroys the odor causing molecule instead of other systems that just mask the smell.

Defoamers and Scale Control

To help you produce sugar more efficiently and avoid costly production issues, Hydrite has a full line of process aids and defoamers designed to keep your facility running smoothly.

Equipment

Hydrite has developed a complete line of equipment technology that makes handling chemicals easier while improving efficiency. Many of our systems are modular, allowing for customization that best suits your needs. Supported by an experienced technical team, processors can maintain complete control over their chemistry delivery and application in a plant with real-time data and insights.

Polymers

We have a defined product line for flocculants, coagulants, and dewatering polymers. Many of these chemistries are used in flume, juice, and wastewater treatment clarifiers. We have a dedicated team that specializes in this sector and offers onsite assistance.

Miscellaneous Chemicals

Hydrite offers total and comprehensive chemical solutions. As one of the largest distributors in North America, we have access to commodity chemicals typically used in a sugar processing facility, with strong purchasing power. Our nationwide network of manufacturing facilities and warehouses are connected with a private transportation fleet for fast delivery.

Hydrite Products

The team at Hydrite works continuously to produce the highest quality products for your industry, while maintaining the highest level of regulatory compliance, food safety, and security of supply. Our SQRA and sourcing teams fully vet our supply chain to make sure that the products we supply are both safe and available when you need them.

Flume Defoamer

Suppressor 3522: A specialty antifoam designed for excellent control of foam in the sugar flumes.

Scale Inhibitor

Hydriscale 1317: A pH buffered blend for the prevention of scale in evaporators, reboilers and distillation columns.

Process Defoamer

Suppressor 3533: A proprietary synthetic blend designed to deliver efficient control of foam in high temp & processing streams.

Suppressor 3543: A 100% active product designed to eliminate foalm in beet sugar processing.

Juice Clarification & Mud Dewatering

Hydrifloc 6237: A polymer blend designed to assist in clarifying the juice liquor.

Odor Abatement

Hydrivail 672: A highly concentrated countervailant odor control product that neutralizes offensive odors.

Hydri-Maize 2759: an aqueous mixture of peracetic acid (PAA) and hydrogen peroxide.

Microbial Control

Hydritreat SB2216: A liquid antimicrobial effective against gram (+) and gram (-) bacteria that can be applied to the flume, pond, cossette mixer and any liquid streams to combat bacteria. Effective in cold temperatures and low pH environments. Rapidly oxidizes hydrogen sulfide and removes odor.

Hydroxycide 1522: EPA registered PAA injected into cooling towers to remove slime forming bacteria and injected into wastewater treatment systems for fecal coliform and control.

Hydrite literature

Contact Us

Connect with a Hydrite representative to learn more on how Hydrite can support your sugar processing goals.