Hydrite's Intervention Chemistry Program

Conditions that encourage bacteria growth increase the possibility of toxins in food, risking foodborne pathogens and the potential outbreak of food-borne illnesses such as E-coli, Listeria, Salmonella, and Campylobacter. To decrease your risk and improve consumer safety, Hydrite has the expertise in meat intervention chemistry you need. Hydrite’s Intervention Chemistry Program can help to reduce bacteria growth and food safety risk and can help to improve shelf life.

Complete Program

Hydrite is a manufacturer of peracetic acid (PAA) and has established an intervention program for foodborne illness pathogens. The program includes chemistry, chemistry delivery systems, process monitoring and controlling systems with subject matter expertise in the art of meat and poultry processing.

Hydrite offers a COMPLETE Intervention program that includes an extensive line of products, integrated equipment, and best-in-class technical service and support. These benefits include:

Antimicrobial Interventions

- Peracetic acid (PAA) USDA FSIS Directive 7120.1

- GRAS Organic acid blends

Chemistry/pH Adjusters

- Caustic and caustic blends

- Chlorine - gas and liquid

- Propylene glycol

- Muriatic acid

- Phosphoric acid

- Sulfuric acid

- Potassium hydroxide

Ingredients

- Citric acid and citrate blends

- Phosphates and phosphate blends

- Coconut Glycerin

- Lactic acid

Intervention Chemistry Technology & Equipment

Hydrite utilizes a systems-and-solutions approach to all our equipment technologies. A key offering to our customers to create operational efficiency is the delivery of chemicals to application points. The correct application of these chemicals is critical. Hydrite delivery systems are uniquely designed for each customer to ensure optimal performance.

Deliver Accuracy

Hydrite uses technology for collecting, analyzing, and documenting concentrations of cleaning, sanitation, and intervention chemistries. Food safety, verification, and validation as well as quality of an applicable finished product are foundational to this creative solution.

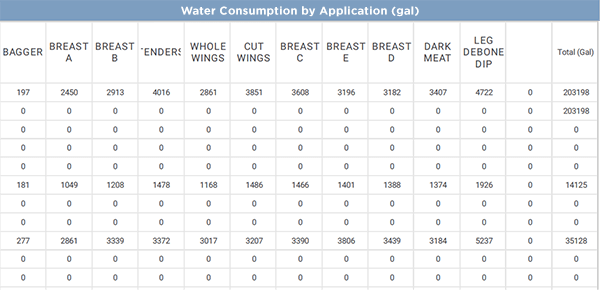

All chemistry is measured within a tenth of a fluid ounce via industrial grade flow meters. Full integration equipment is a PLC based platform that ties directly into facility controls network. Plant employees can control and monitor the performance from any HMI in the plant.

Accuracy and Verification

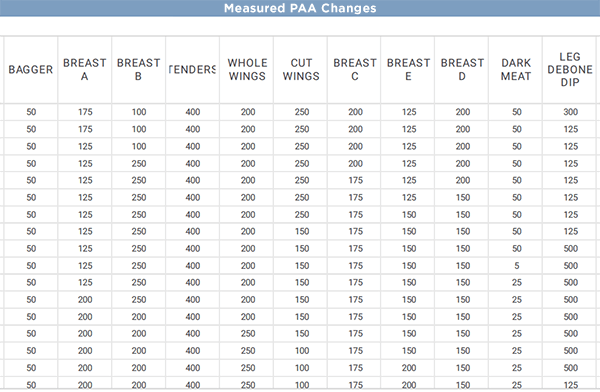

Hydrite's intervention program focuses on multi-hurdle intervention processes by applying physical, mechanical, and chemical interventions. This includes utilizing equipment technology to dose chemistry accurately and consistently, based on the application method. Process monitoring equipment catalogs concentration levels both automatically and using manually entered data to provide a detailed analysis of the system's performance for audit purposes.

Reporting and Verification of Delivery

Users can maintain compliance and quality control by regulating how chemicals are proportioned, monitored, and logged. Detailed usage reports are automatically generated and can be emailed on a regular frequency. Additionally, systems offer real-time PLC access to reports and dashboards, highlighting relevant chemistry parameters and specifications.

Our Solutions

Chemistry

- Peracetic Acid

- Food Grade Lubricants

- Organic Acid Blends (GRAS Approved)

Sanitation

- CIP Cleaners

- Acid Rinses

- Sanitizers

- Disinfectants

- Processing Aids

Equipment

- Systems for Chemical:

- Delivery

- Control

- Handling

Food Safety

- FSPCA

- PCQI

- HACCP

- Sanitation Training

Service & Support

- Real-Time Response

- Innovative Solutions

- Technical Support

- Best-in-Class Service

- Expertise, Experienced & Knowledgeable

Other Solutions

- Contract Cleaning

- Water Treatment

- Foam Control

- & More

Case Studies

Pork Efficacy Study

The effect of Hydrite PAA treatments on the populations of non-pathogenic Escherichia coli surrogates on pig carcasses. The study was conducted at Iowa State University under the direction of Department of Animal Science professor, Dr. James Dickinson, and tested the effect of Hydrite Hydrishield PA 22 HP treatments on non-pathogenic E. coli surrogate inoculum on pig carcasses. Results showing Hydrite Hydrishield PA 22 HP reduced the E. coli population by an average of 1.32 logs.

Intervention Program Reduces Bacteria in Poultry Processing Case Study

Hydrite’s chemical intervention program shows a reduction in both Salmonella and Campylobacter as well as indicator species testing achieving the desired results being one element of safe and wholesome products being produced. Read how Hydrite achieved and maintained target peracetic acid (PAA) and pH concentration for an effective intervention program in poultry processing facilities.

Contact Us

Want to know more about our intervention chemistry solutions? Contact us today.