Fruit and Vegetable Processing

Preparing fruits and vegetables for consumption can include processes like washing, blanching, dehydrating, canning, freezing, fermenting, pickling, and irradiating. These processes provide benefits to consumers and producers alike such as:

-

Extending shelf life

-

Enhancing food safety

-

Reducing food waste

-

Preserving nutrients

-

Improving digestibility

-

Offering consumers convenience and variety

-

Broadening the marketability of produce

Changing dietary habits in the fruit and vegetable processing industry are fueling growth in this area, with demand for ready-to-eat products rising. Manufacturers in this market are identifying ways to optimize and innovate from harvest to storage and distribution.

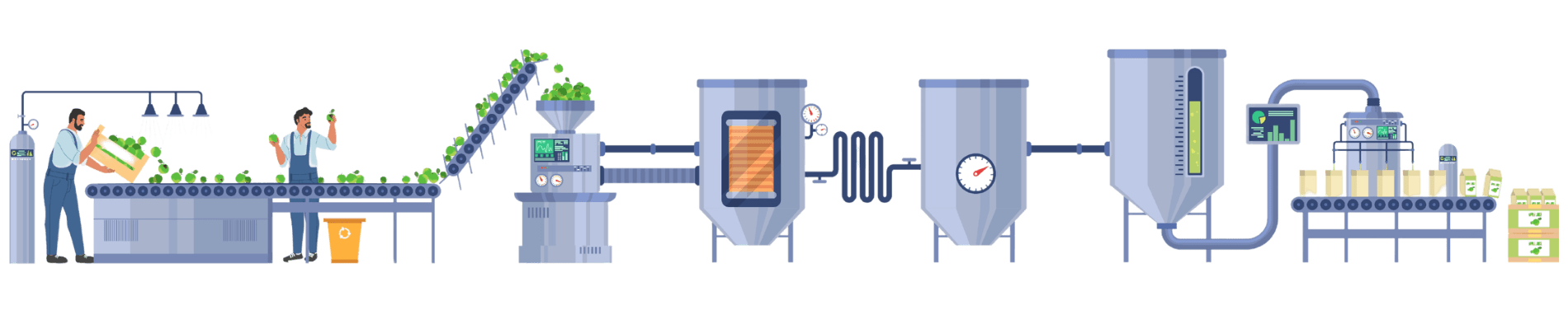

Fruit & Vegetable Production Process

- Harvest

- Receiving

- Precooling

- Washing

- Peeling, trimming, deseeding, cutting

- Disinfection

- Packaging and labeling

- Storage and distribution

Foam Issues Common to Fruit & Vegetable Washing

Food processors face a significant foam problem when washing and processing fruit and vegetable crops. High-starch and protein-rich foods such as peas, corn, and potatoes contribute to foam growth when not treated properly. This can create issues like:

- Overflowing basins and containers

- Loss of vessel space

- Safety hazards such as slick floors

- Throughput and production inefficiencies

Solutions for PRODUCE Processors

FOOD INGREDIENTS

Hydrite is a single source provider of distributed dry ingredients and manufactured liquid chemical additives to fruit and vegetable processors.

- Ascorbic acid

- Citric acid

- Calcium chloride

- Calcium lactate

- Food grade phosphoric acid

- Lactic acid

- Sodium benzoate

FOAM CONTROL

Ideal for water storage prior to the wash process, as well as spray lines during washing, defoamers control surface foam generated by starches and proteins. Hydrite solutions include:

- Suppressor 3110: A 10% silicone emulsion for food processing, meets direct food contact regulations with quick foam knockdown and kosher approval.

- Suppressor 3112: A kosher-approved, formaldehyde-free 10% silicone emulsion for food processing. Provides quick knockdown and persistent foam control.

- Suppressor 3583: 100% active, non-silicone antifoam based on vegetable oil.

- Suppressor ORG 60: Powerful, OMRI listed 100% active product based on vegetable oil.

PERACETIC ACID

Typically added during water treatment and disinfection stages, peracetic acid is a powerful disinfectant due to its high oxidizing potential. Hydrite offers both PAA chemistries and specialized equipment like transfer pumps and metering pumps for safe application in fruit and vegetable applications, with solutions like:

- Hydrishield PA 15% HP: HydriShield PA 15 HP is an aqueous mixture of peroxyacetic acid (PAA) and hydrogen peroxide.

PLANT SANITATION

Plant sanitation has a direct impact on product shelf life and maximizing your production. Your sanitation program also impacts effluent costs, employee safety, and the life of your equipment. Customer and regulatory audits demand that your plant is clean and sanitary. Hydrite produces a complete line of sanitation products for fruit and vegetable processing, and provides service, training and consultative recommendations for optimal results.

- CIP and boil-out detergents

- Sanitizers

- Manual cleaners

- Fruit and vegetable wash compounds

- Blancher cleaners

- Filler/steamer cleaners

- Cook kettle cleaners

- Flume treatment chemicals

- Hand soaps and sanitizers

COMMODITY CHEMICALS

In addition to manufacturing plant sanitation chemicals, Hydrite is one of North America’s largest chemical distributors. We can supply a wide range of commodities including:

- Caustic soda

- Chlorine (liquid and gas)

- Glycols

- Metabisulfite

- Muriatic acid

- Phosphoric acid

WATER TREATMENT

Beyond the conveyor belt, a facility’s water treatment needs can include boiler and cooling systems, closed-loop systems, reverse osmosis feedwater, and wastewater treatment. Hydrite’s comprehensive water treatment program addresses each of these critical areas to ensure smooth and efficient operations.

- Acids and caustic for pH adjustment

- Coagulants for clarification

- Polymers and flocculants for liquid/solid separation

- Phosphorous reduction compounds

- Odor control compounds

- BOD/Solids reduction

THE HYDRITE ADVANTAGE

Our goal is to help manufacturers optimize and innovate their fruit and vegetable production process to stay competitive in a global processed produce industry.

Chemistry Manufacturer

Value-Add Services

Technical Expertise

Robust US & Canadian Distribution Network

Technical Expertise at Your Fingertips

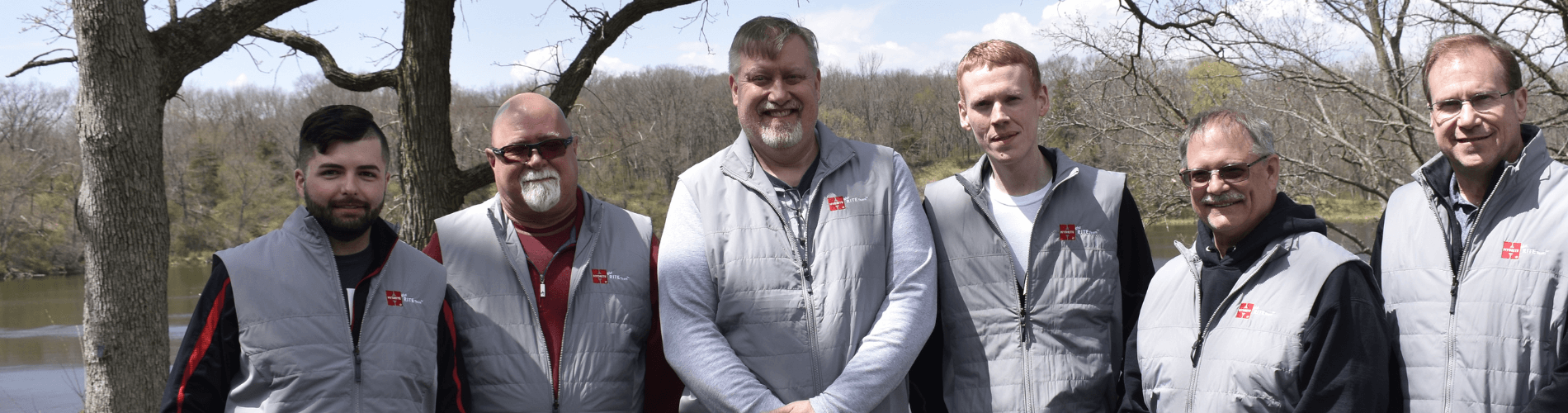

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to support fruit and vegetable processors through technical training, program development, and adjacent technology. Meet the Team

Contact Us

Get in touch with the Hydrite food + foam teams to discover how we can collaborate on your fruit and vegetable processing.