Food Recalls

Food recalls are a critical component of public health and safety, designed to protect consumers from potential hazards associated with contaminated or mislabeled products. These recalls can be prompted by various issues, including bacterial contamination, undeclared allergens, or packaging errors, and they necessitate the swift and efficient removal of affected items from store shelves and homes. Understanding the mechanisms behind food recalls, the processes involved in executing them, and their implications for both consumers and manufacturers is essential for navigating the complex landscape of food safety. Hydrite's food safety team is equipped to help food processors prevent and respond to recalls.

Why do food recalls happen?

Food recalls occur primarily to protect consumers from potential health risks posed by contaminated or mislabeled products. These recalls are often triggered by the discovery of harmful pathogens, such as Salmonella or E. coli, or by the presence of undeclared allergens that could lead to severe allergic reactions. Additionally, recalls can result from packaging errors or mislabeling issues that could mislead consumers about the contents or safety of a product. Common reasons recalls happen include:

- Contamination: Food may be contaminated with disease-causing microorganisms, such as bacteria, viruses, or parasites according to the FDA.

- Foreign Materials: Food may contain physical contaminants like broken glass, metal, or plastic fragments.

- Undeclared Allergens: Food may contain a major allergen, like peanuts or shellfish, that is not listed on the product label.

- Other Issues: Food may have incorrect packaging (mislabeling and misbranding), misleading claims, or incorrect ingredient labels.

How to prevent a food recall

Food recalls can not only hurt the consumer, but can also hurt your brand name. Recalls happen for a variety of different reasons but processors can take preventative steps like:

-

Fostering a Food Safety Culture: An organization-wide commitment to food safety is essential to the long-term success of any production or processing company. By implementing and championing a strong food safety culture, manufacturers are better equipped to prevent and respond to risks.

-

Cleaning: Create and implement thorough, effective cleaning procedures to prevent bacteria.

-

Testing: Regularly sample and test food products and production surfaces to identify potential sources of contamination.

-

Training: Train personnel to follow proper procedures and standards. This can make it easier to conduct a recall if a firm's actions or failures to internal processes are the cause.

-

Labeling: Review and confirm that all labels are accurate, and remove old or obsolete labels from inventory. If you're adding a new ingredient, notify production and receiving personnel of any allergens it contains. You can also provide warehousing personnel with a copy of the specification sheet so they can verify it matches the product.

-

Practicing Recall Preparedness: While it's best to avoid food safety problems, it's unrealistic to expect perfection in complex operations. You can prepare for recalls by having tracing and sanitation procedures in place to limit opportunities for contamination.

How hydrite can help

Hydrite's industry-leading chemistry and equipment offerings are designed to help food manufacturers prevent recalls. Every plant is unique and cleaning protocols must be customized for each location and application. Our team of professionals help food and beverage plants develop customized, cost-effective programs that improve efficiency, reduce operating expenses, and focus on compliance to industry standards and regulations. Hydrite also offers a line of equipment that optimizes chemical storage, handling, monitoring, delivery, and record keeping.

Plant Sanitation

The plant sanitation process is essential to the safe production of foods and beverages. This process is designed to remove soil, microorganisms, and other contaminants from the manufacturing environment. Hydrite offers a full range of products—CIP cleaners, acid rinses, sanitizers, and processing aids—used in the food and beverage industry for a variety of cleaning, sanitization, and disinfection applications.

- Dictate No. 465: A low foaming, EPA registered acid sanitizer for CIP, COP, and other no-rinse applications in the food, beverage, and dairy industry.

- Hydroxysan + No. 494: An EPA registered food contact surface sanitizer formulated for use on hard, nonporous surfaces. Cleans, disinfects, and deodorizes hard, non-porous surfaces by killing many odor-causing microorganisms

- Multiquat No. 455: A concentrated liquid quaternary sanitizer and is approved by the EPA for multiple applications. Used for sanitizing, pre-clean all surfaces and rinse.

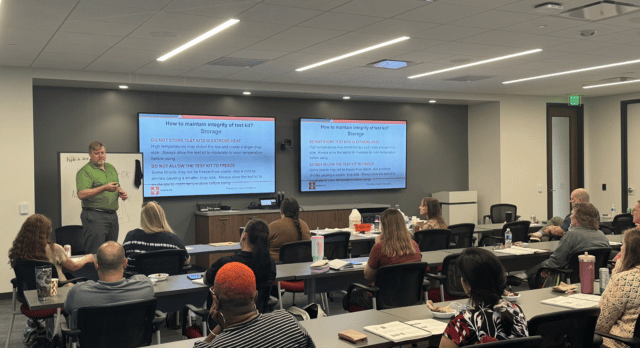

Food Safety Training

Hydrite has decades of experience in the food processing industry. As part of our commitment to raise awareness to food safety behavior changes in the workplace, Hydrite offers in-person and virtual food safety trainings designed to protect consumers, your brand, and your bottom line. Our instructors have decades of industry experience with backgrounds in chemistry, microbiology, and other technical roles.

-

Food Safety & Sanitation Training: Hydrite offers several sessions for cleaning and preventative sanitation in food safety, as well as localized support and service. Our food sanitation programs are in compliance with GFSI, SQF, FSMA, and HACCP. Register

-

Membrane Technology Training: Hydrite offers a comprehensive four-part online training for membrane system processes, cleaning dynamics, chemistry selection, and operations troubleshooting. These trainings ensure employees know the proper treatment of membranes to extend the life of both chemicals and equipment and properly dispose of their solutions. Watch Videos

Technical Expertise at Your Fingertips

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to help prevent and respond to food recalls through technical training, program development, and adjacent technology. Meet the Team

Contact Us

Connect with a Hydrite representative to learn more on how Hydrite can help you prevent, address, and learn from food recalls.