Food Production Lubricants

Lubricants play a crucial role in food production by ensuring the smooth and efficient operation of machinery and equipment in processing plants. They reduce friction and wear on mechanical parts, preventing costly breakdowns and production delays. High-quality, food-grade lubricants are specially formulated to be safe for use in environments where direct contact with food products may occur, maintaining compliance with stringent health and safety standards.

By maintaining optimal machinery performance, lubricants help increase productivity, improve energy efficiency, and extend the lifespan of equipment, all of which contribute to a more sustainable and cost-effective food production process. Additionally, they help reduce contamination risks and support a clean, hygienic environment.

Where are lubricants used in food production?

Lubricants are integral at various stages of food production, from the initial processing of raw materials to the packaging of finished products. They are used to keep machines, conveyors, and mixers running smoothly, supporting consistent performance and efficiency. Some applications include:

- Conveyor Systems - Used to reduce friction and wear on conveyor parts like belts, rollers, and chains.

- Mixers - Used to reduce overheating from crucial parts, which extends the machines lifetime.

- Blenders - Similar to the mixers, blenders are used to prevent overheating from crucial moving parts.

- Packaging Machines - Used to reduce friction on moving parts like gears, belts, and conveyors, in turn making the packaging machine run smoothly without delays or interruptions.

- Cutting & Slicing Machines - These machines improve precision, resulting in more precise and uniform cuts.

- Ovens & Baking Equipment - Proper lubrication ensures that moving parts in the oven operate smoothly, contributing to consistent and precise temperature control, which is vital for uniform baking.

- Extruders - Lubrication provides the machines with the ability to extrude with consistent uniformity and texture.

What are the benefits of using lubricants?

Using lubricants in food production offers several key benefits, including improved machinery efficiency, enhanced product consistency, and extended equipment lifespan. By reducing friction and wear, lubricants help machinery operates smoothly, leading to fewer breakdowns and less downtime. This not only improves productivity but also helps maintain high standards of hygiene and food safety. Proper lubrication also minimizes energy consumption, making the production process more cost-effective and sustainable.

Problems lubricants solve in food production:

- Excessive friction and wear on equipment parts

- Overheating of machinery components

- Frequent breakdowns and production delays

- Decreased equipment lifespan

- Inconsistent product quality

- Increased energy consumption

- Risk of food contamination from unsafe lubricants

- Difficulty in maintaining smooth machine operation

Product spotlight: DRY GLIDE NO. 661

Dry Glide No. 661 is a ready to use silicone conveyor lubricant for use on PET, glass, and can conveyor systems in the food and beverage industry.

Applications:

- Lubrication for PET, glass, and can conveyor systems

- Applied to equipment via brush, allowing more precise application.

- Formulated as ready to use but can be diluted in certain applications

- Consult your Hydrite representative for specific recommendations

Benefits:

- Ready to use formula

- Dry lubrication

- Great lubricity

- Non-phosphated to reduce effluent phosphorous levels

Dry Glide No. 661 Flyer Dry Glide No. 661 Case Study

Lubrication Products

Sani-Pet No. 683

Sani-Pet No. 683 is a liquid, conveyor lubricant for the food and beverage industry that is compatible with Pet bottles.

![]()

![]()

![]()

Glide Right No. 660

Glide Right, No. 660 is a synthetic based, low foaming, concentrated chain lubricant for use in all water types.

![]()

![]()

Hydrilube HD No. 675

Hydrilube HD No. 675 is a low-foam conveyor lubricant for the food and beverage industry, using fatty acid soaps, quaternary ammonium compounds, and surfactants

![]()

![]()

![]()

Dry Glide No. 661

Dry Glide No. 661 is a Ready to Use silicone conveyor lubricant applied via brush for use on PET, glass, and can conveyor systems in the food and beverage industry.

![]()

![]()

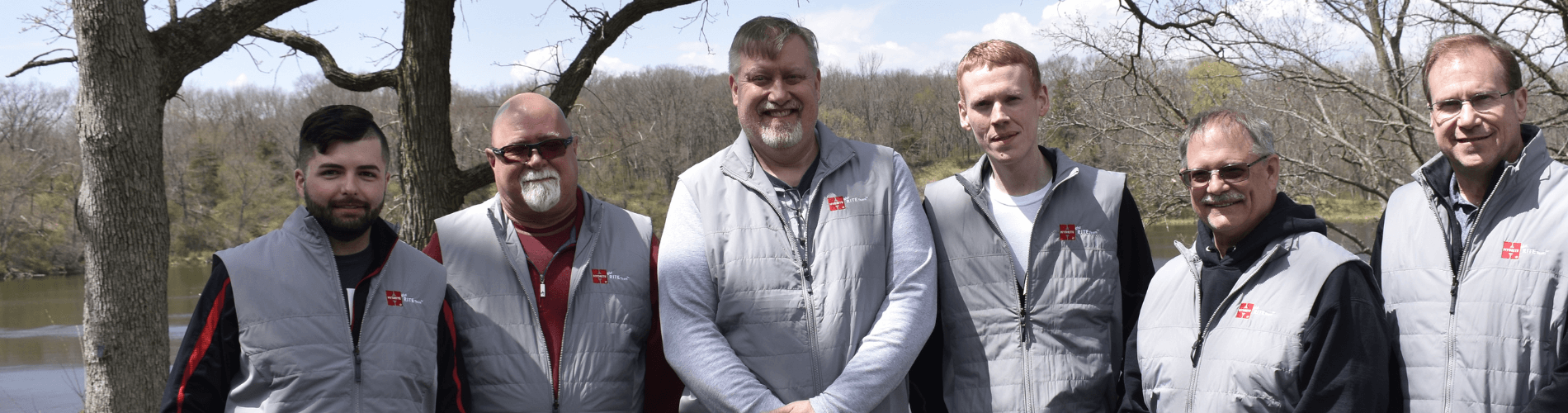

Technical Expertise at Your Fingertips

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to support your process through technical training, program development, and adjacent technology. Meet the Team

Contact Us

Connect with a Hydrite representative to learn more about lubricants for your facility.